Cartridge Mechanical Seal Types

-

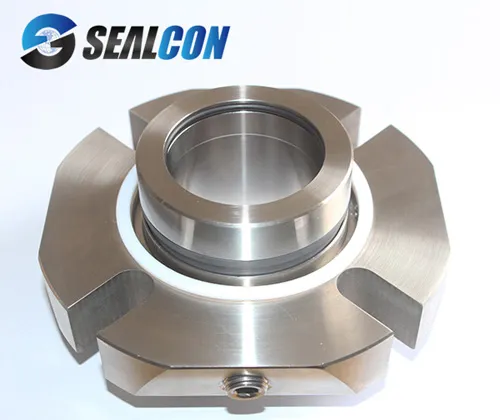

Single Cartridge Seals S11Replacement for:

Single Cartridge Seals S11Replacement for:

- John crane 5610

Single Cartridge Seals S11Replacement for:

- John crane 5610

- Single Cartridge Seals

- Compact design

- Easy installation

-

Single Cartridge Seals S15Replacement for:

Single Cartridge Seals S15Replacement for:

- John crane SE1

Single Cartridge Seals S15Replacement for:

- John crane SE1

- Single Cartridge Seals

- Safmatic seals in pulp and paper industry

- Compact design

- Easy installation

-

Single Cartridge Seals S21Replacement for:

Single Cartridge Seals S21Replacement for:

- Burgmann Cartex SN cartridge

- Burgmann Cartex QN cartridge

Single Cartridge Seals S21Replacement for:

- Burgmann Cartex SN cartridge

- Burgmann Cartex QN cartridge

Features:

- Single Cartridge Seals

- Available in stock

- Compact design

- Easy installation

-

Single Cartridge Seals S22Replacement for:

Single Cartridge Seals S22Replacement for:

- Burgmann Unitex cartridge

Single Cartridge Seals S22Replacement for:

- Burgmann Unitex cartridge

- Single Cartridge Seals

- Available in stock

- Compact design

- Easy installation

-

Single Cartridge Seals S51Replacement for:

Single Cartridge Seals S51Replacement for:

- Depac 270 cartridge

Single Cartridge Seals S51Replacement for:

- Depac 270 cartridge

- Single Cartridge Seals

- Available in stock

- Compact design

- Easy installation

Features of Single Cartridge Seals

- faster and easier replacement of pump shaft seals

- less downtime

- reliable start-up after a sealing change

Advantage of Single Cartridge Seals

- ready-to-install: components include rotating components, bushings and glands

- gage bolts applied for the most gland box

- easy to replace the packing or bearing

- easy to install in uneasy install place

- Used for longer time than non-cartridge mechanical seal

Material Selection for Single Cartridge Mechanical Seal

As one of professional China mechanical seal manufacturers, we place great emphasis on material precision and performance stability. Each Single Cartridge Mechanical Seal is carefully designed and produced according to the working environment and medium characteristics to ensure long-lasting reliability.

For oil-filled motors, sealing performance requirements are higher — the seal must prevent external impurities, sand, and water from entering while also avoiding internal oil leakage. Therefore, we use premium Tungsten Carbide or Silicon Carbide for the sealing faces, ensuring superior hardness, wear resistance, and sealing integrity. These components are key examples of high-performance mechanical oil seal types.

For water-filled motor applications, where the main goal is sand control, we select Alumina Ceramic, Silicon Nitride, or other high-hardness materials to provide effective protection at a more cost-efficient level.

Every material is strictly inspected and matched to the operating conditions, reflecting our commitment to precision engineering and reliable sealing solutions for global industrial clients.

Recommended Applications of Single Cartridge Mechanical Seal

General industrial applications including chemical processing, food and beverage, petrochemical processing, pharmaceutical, wastewater and power generation.

Centrifugal pump, Chemical pump, Slurry pump, Mixer, Agitator, Circulation pump, Submersible electric pump, Reactor, Oil pump etc.

Difference between Cartridge Mechanical Seal and Non-Cartridge Mechanical Seal

Cartridge mechanical seal has a sleeve and gland; non-cartridge seals only have the rotary and stationary ring.

The installation error rate of the Common non-cartridge mechanical sea is higher than the cartridge mechanical seal. Therefore, use cartridge shaft seal can greatly reduce the occurrence of mechanical seal failure.

Since the cartridge mechanical seal does not require any adjustment of the mechanical seal by the installer (such as spring, sealing surface, etc.), only the bolts need to be tightened, which greatly improves the reliability of the mechanical seal installation.

-

May 24 , 2025Explanation of Water Pump Mechanical Seals: Differences Between Water Seals and Oil SealsIntroduction to Water Pump Mechanical SealThe water pump mechanical seal is a very important component in pumps. Its function is to prevent the liquid in the pump body from leaking, ensuring the norma...

May 24 , 2025Explanation of Water Pump Mechanical Seals: Differences Between Water Seals and Oil SealsIntroduction to Water Pump Mechanical SealThe water pump mechanical seal is a very important component in pumps. Its function is to prevent the liquid in the pump body from leaking, ensuring the norma... -

May 22 , 2025The Function and Selection of Bellow Type Mechanical SealsThe Role of Bellow Type Mechanical SealBellows are pipes used to transport various fluids. They are characterized by having a certain waveform elasticity, which can absorb pipeline vibrations and ther...

May 22 , 2025The Function and Selection of Bellow Type Mechanical SealsThe Role of Bellow Type Mechanical SealBellows are pipes used to transport various fluids. They are characterized by having a certain waveform elasticity, which can absorb pipeline vibrations and ther...

- Ceramic Seals Unveiled: Did You Know These Features?

- Water Pump Mechanical Seals: The “Silent Guardians” of Fluids

- Rubber Bellows Seals vs Metal Mechanical Seals: Practical Applications in Aerospace

- Water Pump Mechanical Seal: Ensuring the Effectiveness of the Seal

- The Application and Importance of Water Pump Mechanical Seals

- The Sealing Principle of Ceramic Seals

- Metal Mechanical Seals: Working Principles, Applications and Maintenance

- The Application of Ceramic Seals

English

English français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية ไทย

ไทย čeština

čeština Polska

Polska