CLOSE

Search

-

Hangzhou Sealcon Fluid Machinery Co., Ltd. Set Up A New Office

In March 2017, Hangzhou Sealcon Fluid Machinery Co., Ltd. set up a new office in xihu district,Hangzhou.And the company's factory is still in Jiande,Hangzhou.Office address: A1-3-603 xixi center, weny...view

-

Characteristics Of PTFE Seal

First, material advantages: polytetrafluoroethylene (PTFE), also known as Teflon / Teflon or plastic King (F4), is a copolymer of tetrafluoroethylene monomer, which has the following advantages;1. che...view

-

Advantages Of PTFE

(PTFE) oil seal is one seal of ptfe mechanical seal. It has the following advantages compared to the rubber oil seal.1.Rubber oil seal with a spring pressed tip mouth, the width of the contact with th...view

-

The Installation Of PTFE Mechanical Seals

The installation of ptfe mechanical seals need to pay attention to these points.1. The radial runout of the rotating shaft of the equipment should be less than 0.04 mm, and the axial momentum is not a...view

-

Main Performance Of Bellows

The main performance parameters of the bellows are stiffness, allowable displacement, pressure resistance, cycle life, effective area, working temperature and so on. The main geometric parameters incl...view

-

Elastomer Rubber Bellow Mechanical Seals

Standard and OEM elastomer bellows seals are available.view

Elastomer Rubber Bellow Mechanical Seals

Standard and OEM elastomer bellows seals are available.view -

Pump

Pumps are usually used to lift liquids, to transport liquids or to increase the pressure of liquids, that is, the mechanical energy of the original motive can be changed into liquid energy to achieve ...view

-

Chemical Centrifugal Pumps

A multi-stage centrifugal pump is a collection of two or more centrifugal pumps that have the same functions. In the fluid channel structure, the performance in the first level of medium pressure mout...view

Chemical Centrifugal Pumps

A multi-stage centrifugal pump is a collection of two or more centrifugal pumps that have the same functions. In the fluid channel structure, the performance in the first level of medium pressure mout...view -

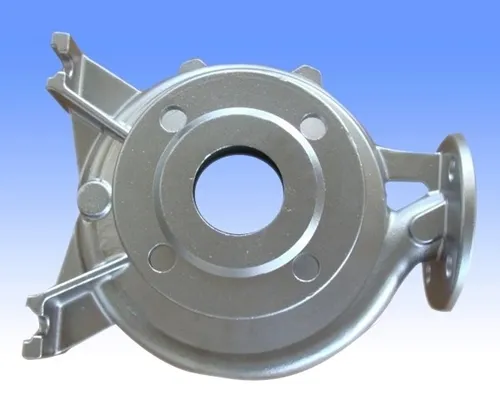

Pump Body

The function of the pump bodyThe pump body is a volute that contains and transports liquid. It consists of a pump cover and a cochlear body. The pump case is a fixed part. The pump body is the suction...view

Pump Body

The function of the pump bodyThe pump body is a volute that contains and transports liquid. It consists of a pump cover and a cochlear body. The pump case is a fixed part. The pump body is the suction...view -

Metal Bellow Mechanical Seals M14M15M16

Performance CapabilitiesTemperature:-75℃ to 200℃Pressure:Up to 20 bar Speed:Up to 23 m/sEnd play/axial float allowance±0.1mmSizes 18mm to 150mm 0.75” to 7”Materials CombinationFace: Carbon, SiC, ...view

Metal Bellow Mechanical Seals M14M15M16

Performance CapabilitiesTemperature:-75℃ to 200℃Pressure:Up to 20 bar Speed:Up to 23 m/sEnd play/axial float allowance±0.1mmSizes 18mm to 150mm 0.75” to 7”Materials CombinationFace: Carbon, SiC, ...view -

Teflon PTFE Bellow Seals T11T12

Performance CapabilitiesTemperature:120℃ max.Pressure:Up to 0.5 barSpeed:Up to 10 m/sEnd play/axial float allowance±0.1mmSizes 16mm to 100mm0.75” to 4”Materials CombinationFace: PTFE glassfibre, C...view

Teflon PTFE Bellow Seals T11T12

Performance CapabilitiesTemperature:120℃ max.Pressure:Up to 0.5 barSpeed:Up to 10 m/sEnd play/axial float allowance±0.1mmSizes 16mm to 100mm0.75” to 4”Materials CombinationFace: PTFE glassfibre, C...view -

The Difference Between Mixing Machine Mechanical Seal And Pump Mechanical Seal

The difference between Mixing machine mechanical seal and pump mechanical sealThe mechanical seal is a mechanical part used to seal the rotary shaft and stop the pump chamber.The sealed part is a cyli...view

English

English français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية ไทย

ไทย čeština

čeština Polska

Polska