CLOSE

Search

Table of Content

[Hide]

The metal bellows (Metal bellows) for the valve stem seal of the control valve is a flexible, thin-walled, multi lateral corrugated tube and shell part (hereinafter referred to as the bellows), which can be made into single layer or multi layer. According to application needs, multilayer bellows can reduce stiffness and enhance effective displacement. In metal bellow seal manufacturer, the combination of one or more series of bellows and their fittings is called bellows, and then the extension valve cover is combined to form the "zero leakage" metal bellows seal of the control valve stem.

There are three kinds of manufacturing methods for bellows: mechanical forming, hydroforming and welding.

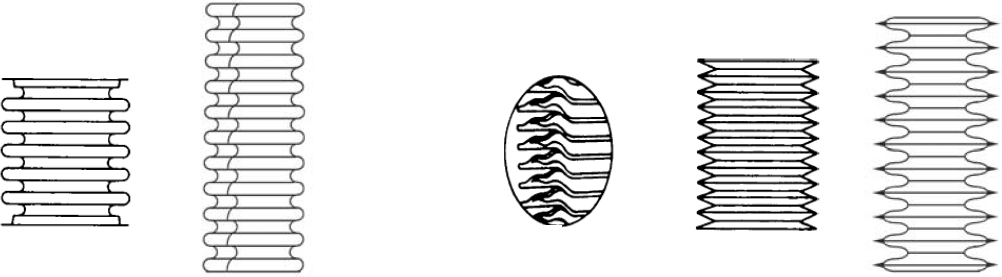

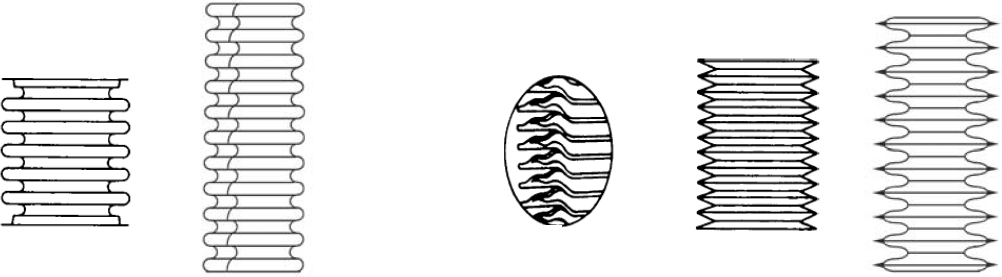

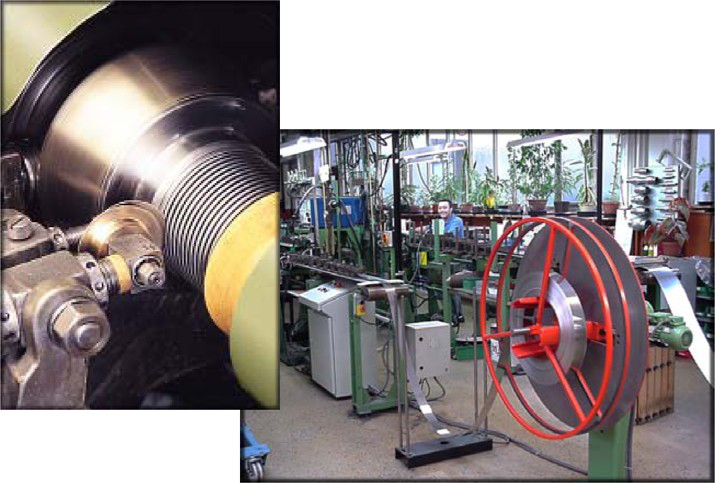

The corrugated pipe made by the mechanical forming method is formed on a metal thin tube with a rotating tool or a single corrugated die, which can be made into single or multi-layer bellows according to the needs. The tube usually selects the cold drawn thin-walled tube (seamless tube) of stainless steel and thin wall tube (weld pipe) welded with thin sheet, which is also an important factor affecting the service life and effect of the bellows. The corrugated pipe made by the thin tube (weld pipe) which is rolled and welded by the rolled strip and sheet is obviously stronger than the corrugated tube made of seamless tube (seamless tube), and the cycle life has a difference of magnitude. See Figure 1. SAMSON selects high quality rolling strip, plate, the use of advanced melting welding technology first roll into thin tube, and then the use of mechanical forming method to produce high quality metal bellows, see Figure 3.

The corrugated tube made by the hydroforming method is to install the thin metal tube in the mold, apply the hydraulic pressure from the inside, and compress the metal tube in the axial direction, and make the bellows. The choice of pipe material is similar to that of mechanical forming. It also selects thin-walled tubes made of cold drawn thin walled tubes and rolled with thin sheets. The shape is the same as figure 1.

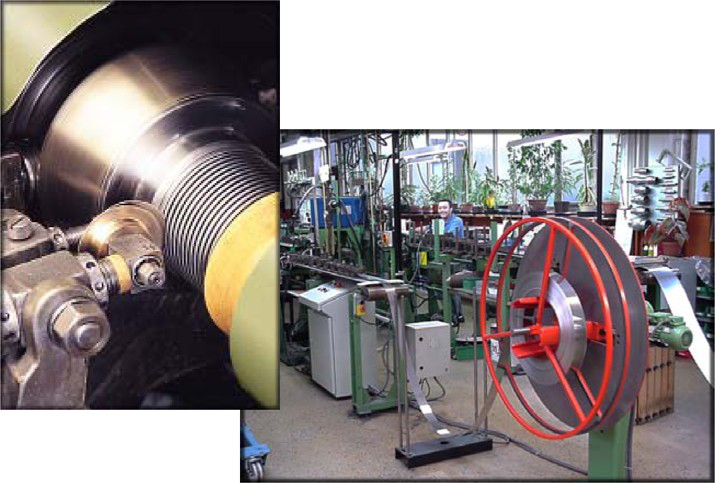

The corrugated tubes made by the welding method are welded together by alternately the outer edges and inner edges of multiple annular elastic metal diaphragms, respectively, as shown in Figure 2.

Figure 1 Figure 2

Figure 3 SAMSON metal bellows manufacturing

There are three kinds of manufacturing methods for bellows: mechanical forming, hydroforming and welding.

The corrugated pipe made by the mechanical forming method is formed on a metal thin tube with a rotating tool or a single corrugated die, which can be made into single or multi-layer bellows according to the needs. The tube usually selects the cold drawn thin-walled tube (seamless tube) of stainless steel and thin wall tube (weld pipe) welded with thin sheet, which is also an important factor affecting the service life and effect of the bellows. The corrugated pipe made by the thin tube (weld pipe) which is rolled and welded by the rolled strip and sheet is obviously stronger than the corrugated tube made of seamless tube (seamless tube), and the cycle life has a difference of magnitude. See Figure 1. SAMSON selects high quality rolling strip, plate, the use of advanced melting welding technology first roll into thin tube, and then the use of mechanical forming method to produce high quality metal bellows, see Figure 3.

The corrugated tube made by the hydroforming method is to install the thin metal tube in the mold, apply the hydraulic pressure from the inside, and compress the metal tube in the axial direction, and make the bellows. The choice of pipe material is similar to that of mechanical forming. It also selects thin-walled tubes made of cold drawn thin walled tubes and rolled with thin sheets. The shape is the same as figure 1.

The corrugated tubes made by the welding method are welded together by alternately the outer edges and inner edges of multiple annular elastic metal diaphragms, respectively, as shown in Figure 2.

Figure 1 Figure 2

Figure 3 SAMSON metal bellows manufacturing

References

Related News

English

English français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية ไทย

ไทย čeština

čeština Polska

Polska